1. According to the nature of the process a. Punching d […]

1. According to the nature of the process

a. Punching die: a die that separates the material along the closed or open contour line. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc.

b. Bending die: A die that bends and deforms a blank or other blank along a straight line (bending line) to obtain a workpiece with a certain angle and shape.

c. Drawing die: It is a die that makes blanks of sheet metal into open hollow pieces, or makes hollow pieces further change in shape and size.

d. Forming mold: It is a mold that directly copies the blank or semi-finished workpiece according to the shape of the convex and concave molds, and the material itself only produces local plastic deformation. Such as expanding die, shrinking die, expanding die, undulating forming die, flanging die, shaping die, etc.

2. Classification according to the degree of process combination

a. Single process die: a die that completes only one stamping process in one stroke of the press.

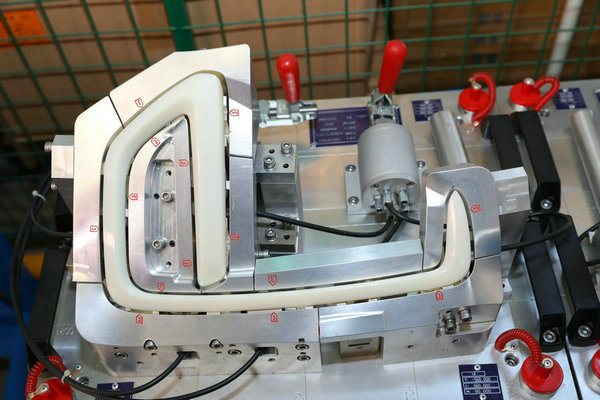

b. Compound die: There is only one station, in one stroke of the press, two or more stamping processes are completed on the same station at the same time.

c. Progressive die (also called continuous die): in the feed direction of the blank, there are two or more stations, in a stroke of the press, two or two steps are completed at different stations one by one More than one stamping process.

3. Classification by product processing method

According to different product processing methods, the molds can be divided into five categories: punching and shearing molds, bending molds, drawing molds, forming molds and compression molds.

a. Punching and shearing dies: the work is done by shearing. Commonly used forms include shearing dies, blanking dies, punching dies, trimming dies, whole-edge dies, drawing dies and punching dies.

b. Bending mold: It is a shape that bends the flat blank into an angle, depending on the shape, accuracy and production volume of the parts, there are many different forms of mold, such as ordinary bending die, cam bending die, curling Die, arc bending die, bending punch die and twisting die, etc.

c. Drawing mold: Drawing mold is to make flat blanks into bottomless seamless containers.

d. Forming die: refers to the use of various local deformation methods to change the shape of the blank. Its forms include convex forming die, curling edge forming die, necking forming die, hole flange forming die, and round edge forming die.

e. Compression mold: It uses strong pressure to make the metal blank flow and deform into the desired shape. Its types include extrusion die, embossing die, embossing die, and end pressure die.

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP