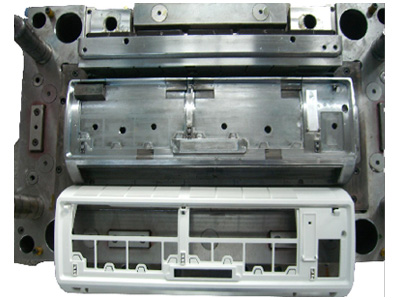

1. For the air needle panel injection mold, when the ai […]

1. For the air needle panel injection mold, when the air needle is pressed into the deflation, the air intake imbalance is most likely to occur, which makes debugging more difficult. Its main performance is shrinkage. The solution is to check the gas fluency during deflation;

2. The temperature of the compound is one of the key factors that affect the normal production of the injection mold: the quality of the gas-assisted molding is more sensitive to the temperature of the compound. Excessive nozzle material temperature will cause product material flower, scorching and other phenomena; too low material temperature will cause cold glue, cold mouth, blocking gas needle and other phenomena. The phenomenon reflected by the product is mainly shrinkage and material consumption. The solution is to check whether the temperature of the rubber compound is reasonable.

3. In manual state, check whether there is any overflow phenomenon when the needle-sealing nozzle returns. If there is this phenomenon, it means that the gas-assisted sealing needle fails to seal the nozzle. During gas injection, high-pressure gas will flow back into the feed pipe. The main phenomenon is the large area of scorch and material scorching at the nozzle, and the time for returning material is greatly reduced, and gas will be discharged when the needle is opened. The main solution is to adjust the length of the sealing rod.

4. Check whether the gas-assisted induction switch is sensitive, otherwise it will cause unnecessary losses.

5. The gas-assisted molded products rely on gas pressure, and the product can be properly reduced when the product shrinks. Mainly to reduce the pressure and space inside the product, so that the gas can easily puncture to the place where the glue is thick to make up the pressure.

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP