1. The place where the prefabs are placed must be level […]

1. The place where the prefabs are placed must be level.

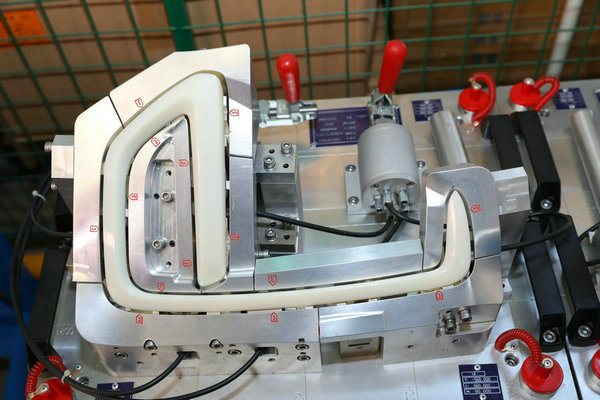

2. Before prefabrication, mold release agent or oil must be wiped in the mold. .

3. The mould with concrete must be laid flat. .

4. It is forbidden to prefabricated components below 4 degrees.

5. Moulds that are temporarily not used after demoulding must be placed neatly after cleaning. Prevent deformation. .

6. The percussion tool used during demolding must be a wooden hammer or a leather hammer.

7. When demolding, use a stripper or pad with sack pieces or pad straw bags or waste tires to prevent damage to the preforms and molds.

8. The vibrating platform should be cleaned frequently, kept flat, and cleaned up at the end of work.

9. When prefabricating large components, if the mold is directly placed on the ground and the vibrating rod is used, the head of the vibrating rod must be covered with a leather sleeve, otherwise the service life of the mold may be reduced.

10. It is easy to deform when prefabricating large or heavier components. It is recommended to use wooden boards or clamps or use a finished iron frame.

11. When the temperature is high in summer, the prefabricated parts must be covered with sack pieces or straw bags or sunshade nets to prevent the prefabricated parts from cracking in the sun, and the prefabricated parts must be sprinkled with water for maintenance on time.

12. The pipes used when making prefabricated blocks with holes must be drawn out in time, and they cannot be drawn out after a long time.

13. When the mold is stuck with cement and it is difficult to clean up, it is forbidden to clean it with iron tools. It is recommended to use dilute hydrochloric acid or oxalic acid to soak, and then clean it with a soft cloth

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP