When the plastic solidifies in the mold cavity to form […]

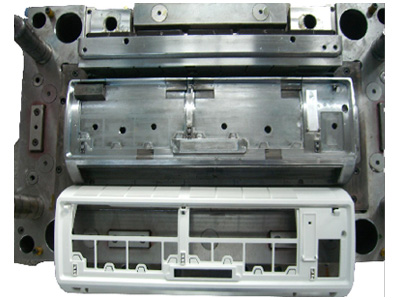

When the plastic solidifies in the mold cavity to form a plastic part, we must open the cavity in order to take out the product smoothly, that is, the mold must be divided into parts. That is, the fixed mold and the movable mold are two parts, and the contact surface of these two parts is the parting surface.

The points to be paid attention to when selecting the parting surface are as follows:

1. It should be selected at the largest cross-section of the outline dimension of the injection molded part to facilitate the smooth removal of the injection molded part from the cavity.

2. The surface quality and appearance requirements of injection molded parts and the accuracy of size and shape should be guaranteed.

3. The parting surface should be designed to facilitate exhaust and prevent overflow.

4. The purpose of the parting surface design should be to facilitate the processing of the mold and simplify its structure.

The selection of the parting surface of the plastic mold is not only related to the normal molding and demoulding of the plastic parts, but also affects the mold structure and manufacturing cost to a certain extent. In summary, the overall selection principle of the parting surface is to ensure the quality of plastic parts, facilitate product demoulding, simplify the mold structure, meet customer needs, design satisfactory molds for customers, manufacture high-quality molds, and produce high-quality products. .

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP