The selection of two-color injection mold materials is […]

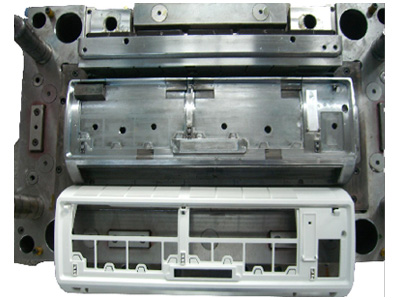

The selection of two-color injection mold materials is a prerequisite to ensure the quality of mold processing. Therefore, special attention must be paid to the physical and chemical properties of the materials and the selection of processing to design a reasonable mold.

Combined with traditional mold design, CAE technology and computer-aided engineering have great advantages in improving productivity, ensuring product quality, reducing costs, and reducing labor intensity. How to choose the material of the two-color mold?

1. Good thermal stability:

The shape of the parts of plastic two-color molds is often complicated and difficult to process after quenching. Therefore, you should try to choose those with good thermal stability. When the mold is formed by heat treatment, the linear expansion coefficient is small, the heat treatment deformation is small, and the dimensional change caused by the temperature difference The rate is small.

2. Sufficient surface hardness and wear resistance:

The hardness of the plastic mold is usually below 50-60HRC, and the heat-treated mold should have sufficient surface hardness to ensure that the mold has sufficient rigidity. When the mold is working, due to the filling and flow of the plastic, it has to withstand greater compressive stress and friction. The mold is required to maintain the accuracy of the shape and the stability of the dimensional accuracy to ensure that the mold has a sufficient service life.

www.xlpmould.net

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP