Automobile plastic mold processing explained. In terms […]

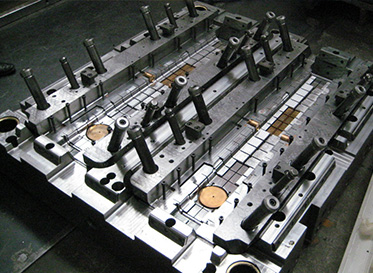

Automobile plastic mold processing explained. In terms of molds, micro injection molding has higher requirements for processing equipment than traditional injection molding. Micro injection molding usually has two trends in plastic mold processing: the first is to use mirror spark machining to ensure high precision , It is best to use graphite electrodes for EDM, because the loss of graphite electrodes is much smaller than that of ordinary copper electrodes.

The second more commonly used processing method is to use electroforming. The electroforming process can ensure very high accuracy, but the disadvantage is that the processing cycle is long, each hole must be processed independently, and if there is a slight damage in production, it cannot be repaired. , Only replace damaged acupoints. In terms of mold, mold temperature is also a very important parameter for micro-injection. Automobile plastic mold processing explains that customers facing high-end needs, the more commonly used approach is to borrow the concept of high-gloss injection molding and introduce a rapid heating and cooling system.

In theory, high mold temperature is very helpful for micro-injection, for example, it can prevent thin-wall filling difficulties and lack of material, but too high mold temperature will bring new problems, such as cycle lengthening and shrinkage deformation after mold opening. Therefore, it is very important to introduce a new mold temperature control system. During the injection molding process, the mold temperature can be increased (which can exceed the melting point of the plastic used), so that the melt can quickly fill the cavity, and prevent the melt from reducing the temperature during the filling process. It is fast and causes incomplete filling; and when demolding, the mold temperature can be quickly reduced, kept at a temperature slightly lower than the thermal deformation temperature of the plastic, and then the mold is opened and ejected.

www.xlpmould.net

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP