There are several injection molding issues that need to […]

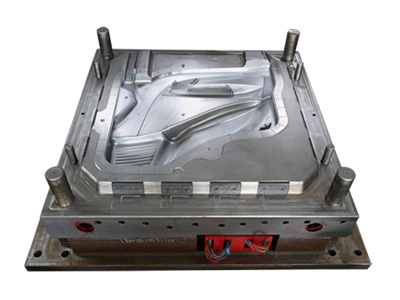

There are several injection molding issues that need to be paid attention to during the trial period of automotive plastic molds

1 How to feed plastic molds

2 Is there a lot of approval for plastic mold production?

3 Whether there is poor exhaust at the position where there is a post process

4 Is the product taking out smoothly?

5 The rationality of the manipulator in the process of taking out the structure of the product

6 Rationality of product stress release

7 Whether the size of the product is large or small

So why do these issues need to be paid special attention? Each company will have a test mold table during the mold test phase. It needs to be checked for molds and product sizes, etc., but these issues will directly affect the normal volume of automotive plastic molds. Smooth mass production after delivery, so these issues need to be more carefully confirmed.

1 The way the plastic mold is close to the glue will affect the processing of the product and the way the product is glued, as well as whether the size is better adjusted and whether there is a hidden danger of shell cracking.

2 If there are too many batches, there will be a lot of wasted labor in normal production, and manual processing will increase the difficulty of quality control.

3 If there is a gold or silver spraying process, and if the exhaust cylinder and exhaust groove design are reasonable, it will cause the product to corrode after the process and crack, and the surface defects are obvious hidden dangers

4 If the product is not taken out smoothly, it means that if the reason for the unbalance of the machine angle is eliminated, it means that the plastic mold itself has not been optimized well, which will cause the mold to be degummed during the mass production process and the product surface will be strained.

5 If the car plastic mold is not easy to pick up the product with the robot, or the suction cup of the robot picks the product is unreasonable, it will cause production safety hazards and the phenomenon of plastic mold product surface packaging.

6 If the rationality of stress release is not well evaluated, if the cooling time is too short and the cycle is too fast during the production process, the corrosion of the process paint after adding will cause shell cracks and poor functionality.

7 The size of the plastic mold product has large and small heads. If it is not the design requirement of its own, it needs to be solved by optimizing the mold in the early stage, because if it is not solved, it will lead to difficulties in mass production. Difficulty in adjustment.

www.xlpmould.net

Add: No.9 Hengtai Road, Tinghu Economic Development Zone, Yancheng City, Jiangsu, China

Tel: 0086-515-89806501

Fax: 0086-515-89806502

E-mail: [email protected]

TOP

TOP